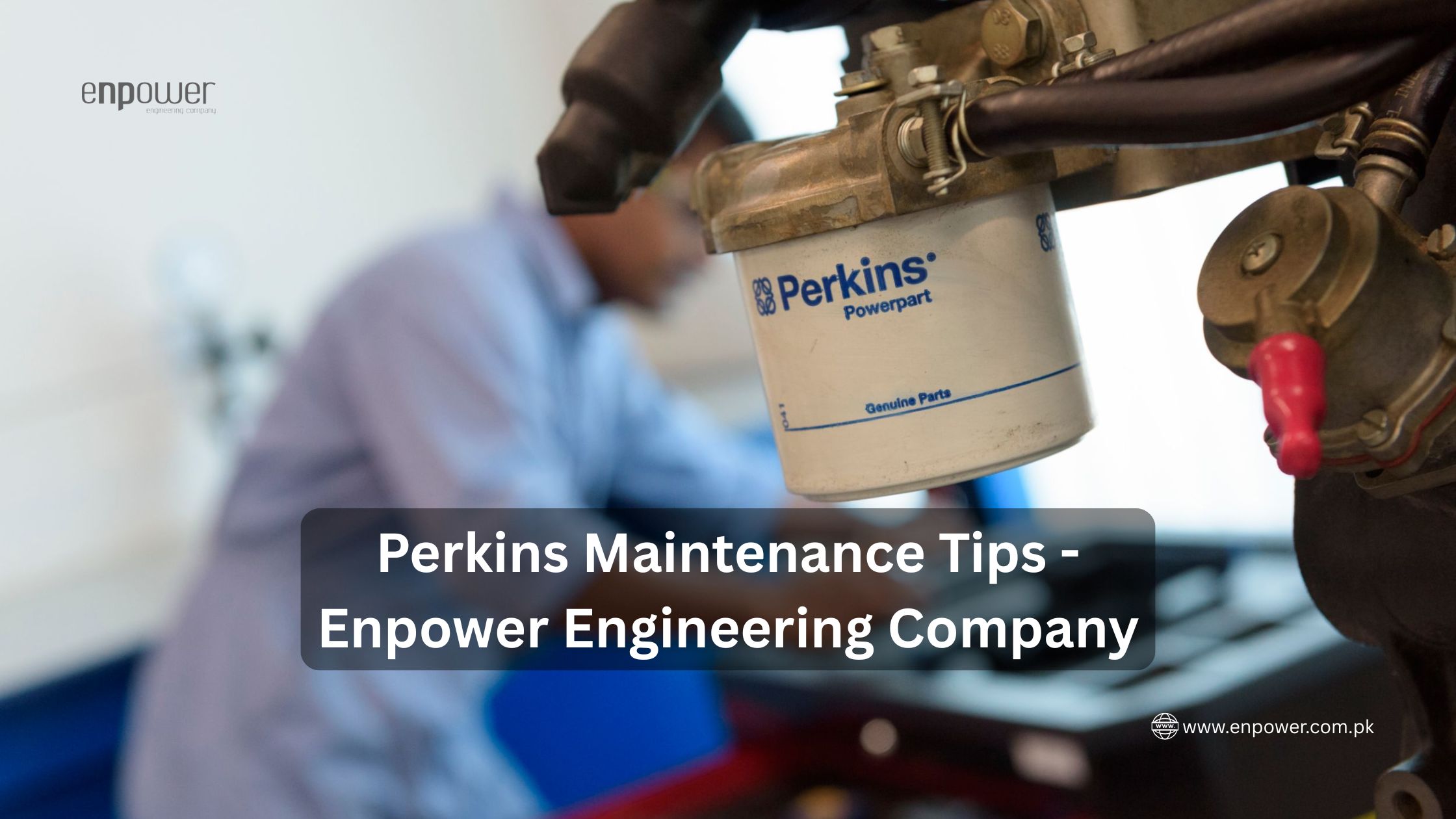

Perkins Generator Maintenance Tips: How to Make Your Generator Last for Decades

Every business owner and facility manager in Pakistan wants one thing: a generator that starts instantly the moment the power goes out. However, the biggest concern for many is the fear of a sudden engine failure during a critical power cut. While Perkins engines are built to be incredibly tough and are known for their world-class durability, they are still machines that require the right care to remain reliable.

If you ignore regular checkups, a small, cheap-to-fix issue can quickly turn into a very expensive engine overhaul. At Enpower Engineering Company, our mission is to help you protect your investment. We believe that with the right maintenance schedule, a Perkins generator should not just last for a few years, but for 20 years or more.

The Danger of Using “Cheap” Local Parts

It is often tempting to save a few thousand rupees by buying local filters or low-quality engine oil from the open market. In the dusty, hot, and harsh environment of Pakistan, this is a huge mistake that can ruin your engine.

Perkins engines are designed with very tight tolerances. Non-genuine filters often fail to stop microscopic dust particles from entering the fuel system or the combustion chamber. This dust acts like sandpaper, slowly scratching the cylinder liners and pistons. Over time, this leads to power loss, black smoke, and high fuel consumption. To keep your engine smooth and fuel-efficient, you must always use Genuine Perkins Filters and high-grade oil recommended by Enpower Engineering Company.

Three Essential Steps for Maximum Engine Life

To ensure your generator stays in top condition, our engineering team recommends following these three foundational steps:

- The 250-Hour Service Rule In Pakistan, where generators run frequently, we don’t measure life in kilometers; we measure it in hours. For a Perkins engine, the standard service interval is 250 operating hours. This is the time when the engine oil loses its ability to lubricate and filters become clogged. Changing them strictly every 250 hours ensures that the internal parts of your engine are always protected by fresh, clean oil.

- Keeping the Cooling System Clean Dust is the silent killer of generators in Pakistan. It blocks the radiator fins, which prevents air from cooling the engine. If a generator overheats, it can cause the cylinder head to warp or gaskets to blow. Regularly cleaning the radiator with low-pressure air or water and ensuring you are using a high-quality coolant (not just plain tap water) will prevent 90% of overheating issues.

- Monthly Battery and Electrical Checks It is a frustrating reality: many generators fail to start simply because the battery is weak or the terminals are corroded. Because generators often sit idle for days, the battery can lose its charge. We recommend checking the battery voltage and cleaning the terminals once a month. A healthy battery ensures that your Perkins engine roars to life exactly when you need it.

The Risk of “Wet Stacking”

A common mistake made by many users in Pakistan is running a large generator on a very light load (less than 30% of its capacity). Perkins engines need to work hard enough to reach their optimum operating temperature. If they run too “cold” for too long, unburnt fuel builds up in the exhaust system—a problem known as “Wet Stacking.”

This can damage your engine and reduce its lifespan. At Enpower Engineering Company, we suggest regular “Load Bank Testing” if your daily load is low, to ensure the engine stays clean and powerful.

Why Professional Servicing is Better

Sometimes, an engine sounds perfectly fine to the untrained ear, but it might have hidden issues like a leaking water pump or a worn-out belt. Our team at Enpower Engineering Company doesn’t just change the oil; we perform a 50-point health check. We use specialized diagnostic tools to check the fuel timing, alternator health, and control panel settings. This “Preventive Maintenance” catches small problems early, saving you from the stress of a total breakdown and the high cost of emergency repairs.

Conclusion: Invest in the Future of Your Power

Your Perkins generator is a high-performance machine that deserves high-performance care. By following a strict maintenance schedule and using only genuine parts, you can avoid 90% of common generator failures.

Enpower Engineering Company offers customized maintenance contracts where our experts take over the responsibility of your power backup. We ensure that your generator is always “Ready to Run,” giving you the peace of mind to focus on your business.

Don’t wait for a breakdown to call the experts. Contact Enpower Engineering Company today to book a professional health check for your Perkins generator!

Frequently Asked Questions

Why is my diesel consumption so high?

If your generator is old or has not been serviced on time, it will consume more fuel. In Pakistan, people often use low-quality diesel which creates carbon buildup inside the engine, leading to higher consumption. Perkins engines solve this problem with their advanced fuel systems that use every drop of fuel efficiently.

How can I control diesel consumption in my factory?

The easiest way is to maintain a balanced load on your generator. Running a generator at a very low load actually wastes more diesel. Enpower Engineering Company provides professional load audits to help you run your generator at the ideal level for maximum savings.

What is the best fuel-saving trick for generators?

The real “trick” is Preventive Maintenance. Replacing filters with genuine parts on time reduces the pressure on the engine. This allows the engine to run smoothly and provide more backup while consuming much less diesel.

How does air quality in Pakistan affect my generator?

High dust levels in cities like Lahore or Karachi can clog air filters much faster than the standard 250-hour limit. If you operate in a very dusty area, we recommend checking your air filters every 50 hours to maintain fuel efficiency and engine health.